Study on alternative electrolytes

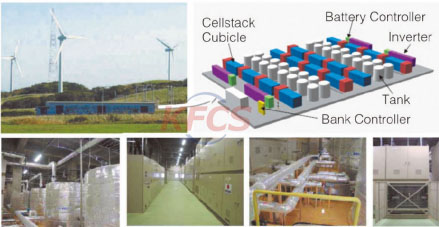

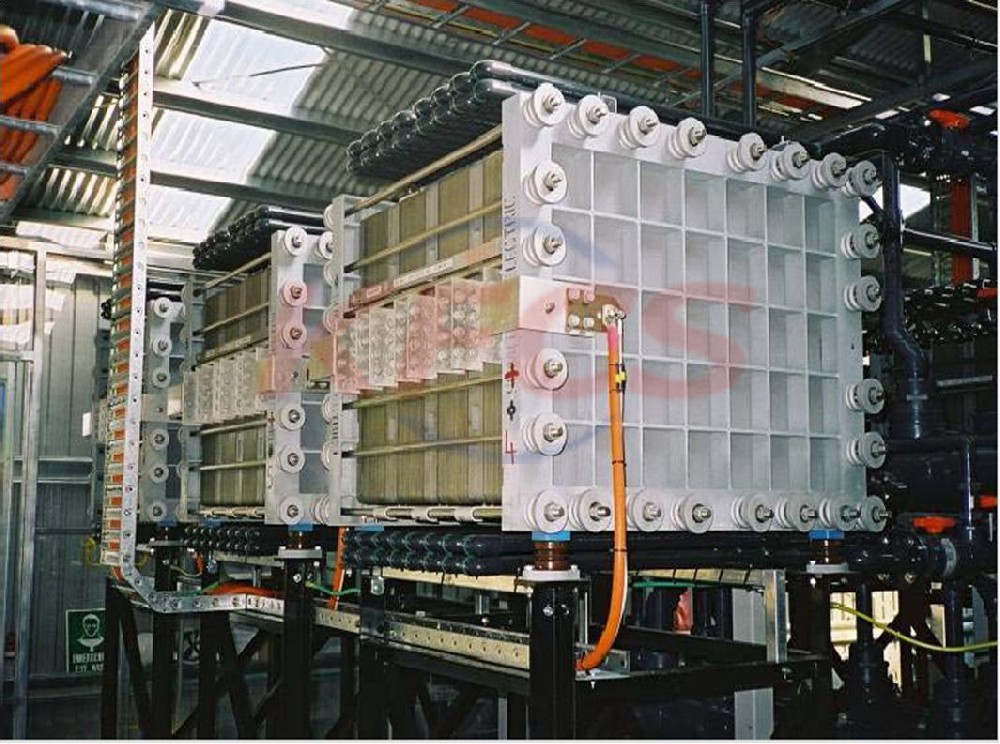

In view of the cost challenge faced by vanadium redox flow battery (vrfb), many alternative electrolytes are being actively studied, and more and more attention is paid to the production of low-cost redox electrolytes using the rich elements on the earth. In view of the various interrelated requirements for the electrolyte of flow battery (e.g. potential, solubility, stability, cost), these alternatives do not show the same market and technical situation as vanadium redox flow battery (vrfb), but some low-cost electrolytes are of particular interest.

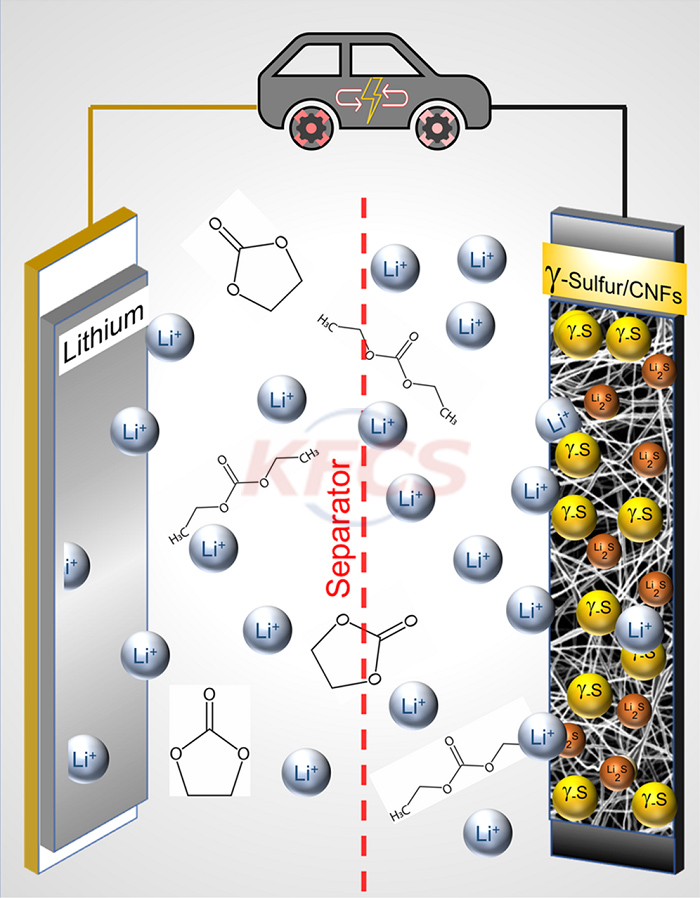

Abundant inorganic elements, such as iron, sulfur, manganese or iodine, dissolved in suitable aqueous electrolytes are still of interest. Many materials are produced as products or by-products of commodity scale industrial processes, which provides the benefits of large-scale production and the use of existing production infrastructure.

In addition, the use of waste may provide another source of income for chemical manufacturers and be consistent with process sustainability goals. These methods are currently challenged by several factors: the need to upgrade materials to electrochemical grade, the technical properties of chemicals, and the cost of other system components. High purity electrolytes are needed to prevent side reactions inside the liquid flow battery, especially the generation of hydrogen on the negative electrode, which can be catalyzed by the deposition of metal impurities on the electrode.