New proton exchange membrane fuel cell that can operate at -20 to 200 degrees Celsius

New proton exchange membrane fuel cell that can operate at -20 to 200 degrees Celsius

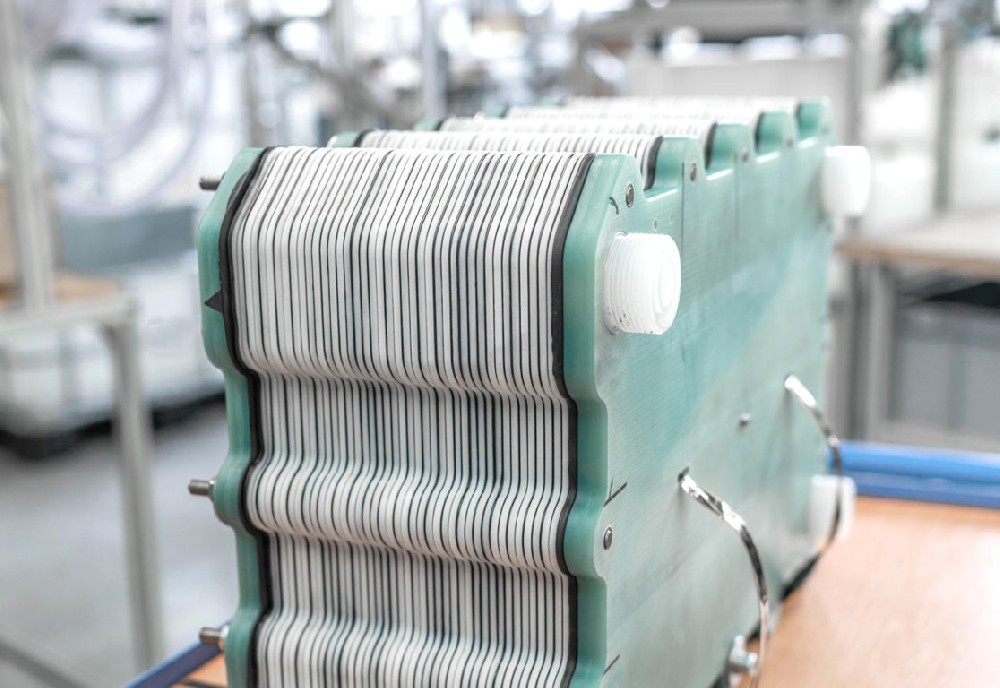

A proton exchange membrane fuel cell (PEMFC) is a battery that re-converts chemical energy from the electrochemical reaction between hydrogen and oxygen into electricity. While these batteries can be very promising options, they can only operate in a limited temperature range, such as 80 to 90 degrees Celsius or 140 to 180 degrees Celsius.

Researchers from the Chinese Academy of Sciences, Tianjin Normal University and Tianjin University have recently designed a new proton exchange membrane fuel cell that can operate over a wider range of temperature variations, reaching minus 20 to plus 200 degrees Celsius. Their paper, published in the journal Nature Energy, could lead to widespread adoption of proton exchange membrane fuel cell technology, while also reducing the price of its manufacture.

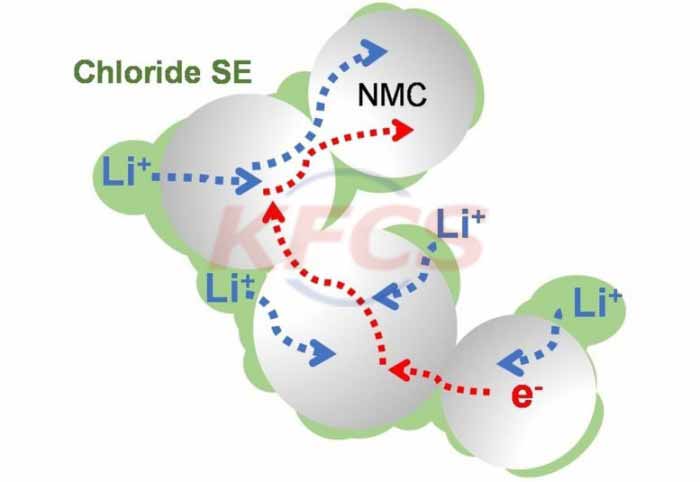

"When we consider phosphoric acid (PA) leakage from polybenzimidazole (PBI) membranes, based on the concept of acid-base interactions, we assume that one molecule of benzimidazole will absorb one molecule of phosphoric acid (PA)," said one of the authors of the paper. Nanwen Li told us. "On the other hand, all the other PA molecules in the PBI membrane are mostly retained through hydrogen bonding interactions. It's like a dog chain that binds a dog and allows other dogs to follow the dog because of blood ties. However, If we can create a kennel and close the front door, all the dogs in the kennel will not be able to get out."

The main aim of the latest study by Li and his colleagues was to create a membrane that could absorb phosphoric acid (PA). To further enhance its ability to capture PA, the researchers took advantage of the so-called "capillary siphon effect," by which liquids can be easily absorbed.

When impinging on a standard membrane with capillary siphoning, the liquid may not simply be ejected. Therefore, the researchers decided to use Tröger's base (TB) polymers to create films that provide ultra-high intrinsic micropores.

Li explained, "The ultra-micropores in the TB polymer act as capillaries for PA absorption and retention, like a dog's kennel. By tuning the chemical structure of the monomer, the pore size and distribution of the polymer membrane can be controlled. The pore size is about approx. Films that are 3.5 angstroms (Å) exhibit the best siphoning effect of PA molecules, and thus have the best electrical conductivity stability and fuel cell performance over a wide operating temperature range."

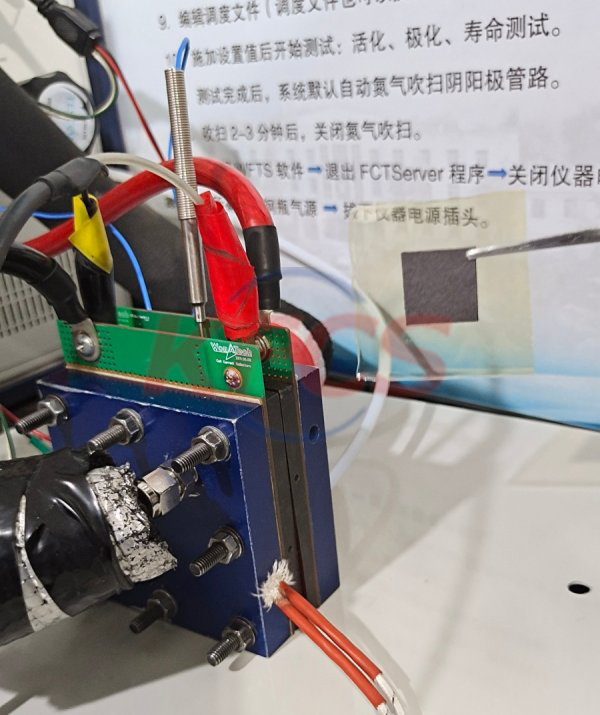

Fuel cells work by reacting oxygen with hydrogen, ultimately producing electricity and water. The proton-conducting membrane contained in the PEMFC is coated on both sides with catalytic substances to initiate an electrochemical reaction between the anode (hydrogen) and cathode (oxygen) inside the cell.

Furthermore, the main functions of the membrane are two-fold: one is to conduct protons catalyzed at the anode to the cathode and combine them with oxygen, ultimately producing water, and the other is to force electrons (ie, electrical energy) at the anode through an external circuit Catalytic generation, where they complete the circuit and produce water," Li said. "One can think of a fuel cell as a highly controlled catalytic combustion of hydrogen and oxygen, which doesn't explode as it does when ignited, but instead releases electricity as needed. Electrolysis, or water splitting, is actually the opposite, where you input electricity to split water into hydrogen and oxygen. "

Using the phosphoric acid (PA)-doped ultra-microporous membranes they created, Li and his colleagues are ready to make fuel cells that can operate under very large temperature changes. This is a remarkable achievement, as previously developed PEMFCs can only operate within a limited temperature range.

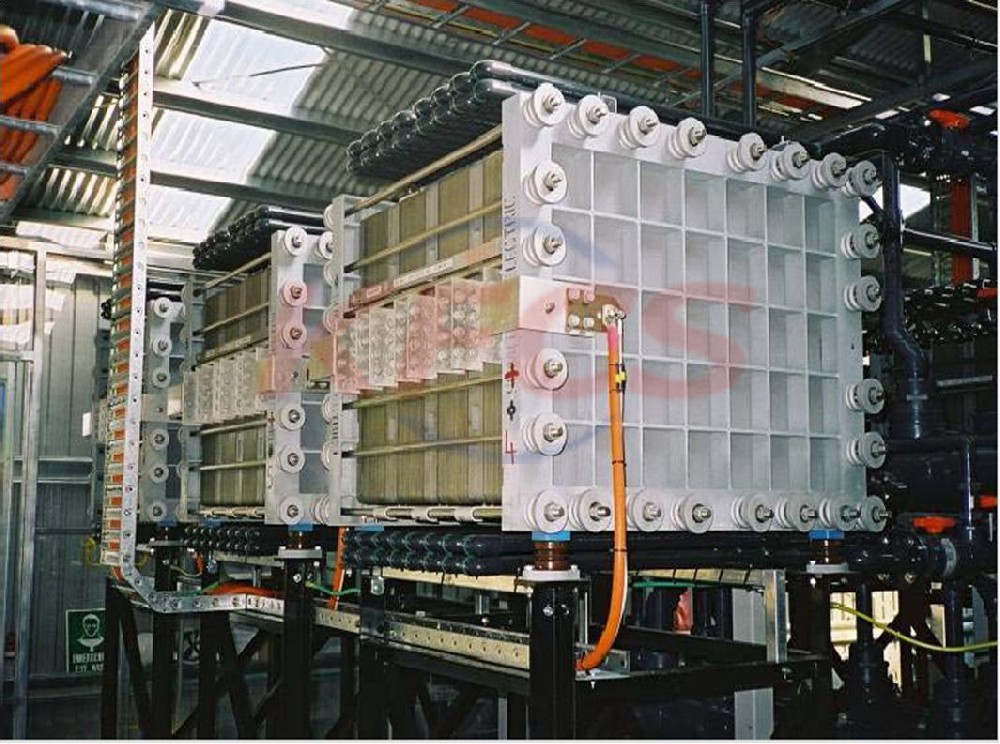

"Using our design, the fuel cell stack will be greatly simplified," Li said. "We believe that the siphon effect of PA absorption into ultrafine pores is of great significance for the development of high-performance high-temperature PEMFCs, and will also improve the entire fuel cell system to operate without an auxiliary heating system."

New membrane and cell designs could soon lead to better-performing proton exchange membrane fuel cells, while also drastically reducing their manufacturing costs. In their next study, Li and his colleagues plan to apply capillary siphoning to the catalyst layer as well, to improve its effectiveness and reduce catalyst loading.

Additionally, they will focus on fine-tuning the size of the membrane pores and the distribution of mixing, copolymerization, and crosslinking. This could ultimately contribute to additional improvements in fuel cell stability and conductivity.

"We also hope to design and fabricate PBI systems with the same ultrafine pores as the membranes we used, which may be easier to apply to the energy industry," Li added. "Furthermore, the siphon effect we generate can also be used in the catalyst layer, keeping the PA molecules inside the catalyst layer, thus avoiding the adverse effects of phosphate poisoning of the Pt (platinum) catalyst. Therefore, we expect high temperature proton exchange membrane fuel cells High catalyst utilization and low catalyst loading will be achieved.”