Chinese and American researchers develop new 3D thermal management mesh to improve EV battery safety

Chinese and American researchers develop new 3D thermal management mesh to improve EV battery safety

Despite the benefits of high-energy lithium-ion batteries and fast charging technology, the development of electric vehicles is still challenging. For example, the low heat dissipation efficiency of the battery leads to safety problems. According to foreign media reports, Chinese and American researchers set out to find a cost-effective battery thermal management strategy to keep the battery temperature within a safe range. Researchers have developed a 3D, interconnected and thermally conductive boron nitride mesh, which can greatly improve the thermal conductivity.

The traditional gas or liquid cooling method has the problems of space limitation and electric leakage in the charging process. As a solid cooling medium, new phase change materials have attracted more and more attention. PW is an ideal material with low heat capacity and heat leakage, but it is easy to manage heat leakage.

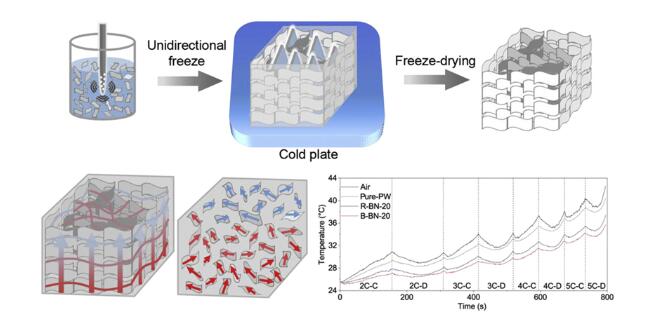

In this study, the researchers constructed a highly ordered and interconnected hexagonal boron nitride (h-BN) network through the ice template method and introduced it into paraffin to improve the thermal conductivity of the material.

In the management of battery heat dissipation, h-bn/pw composites show good heat dissipation performance. When the load of h-BN is 20 wt%, the composite can ensure a highly ordered network state, and the thermal conductivity is as high as 1.86 W M − 1 K − 1, which is 4 times higher than the randomly distributed h-BN and nearly 8 times higher than the most basic PW. The results showed that the maximum surface temperature of the battery decreased by 6.9 ℃ when the battery was continuously charged and discharged at 2-5 ℃. The researchers believe that this shows that the process has high application potential in battery thermal management system.

Professor Zhang Bing of Zhejiang University explained: "the researchers designed a 3D boron nitride network and systematically studied its impact on the thermal management performance of the battery. The researchers found that the hexagonal boron nitride thermal network (h-BN) was constructed by ice template method under different temperature gradients , showing structural differences in different directions. Generally speaking, structure determines performance. Different structures in different directions mean a wider range of performance. The h-BN / Pw composite made of paraffin can achieve excellent anti leakage performance and ultrafast heat dissipation performance in lithium-ion batteries. "